一(yī)、拋光過度:在日常拋光過(guò)程中遇到的問題就是"拋光過度",就是指(zhǐ)拋光的時間越長,模具表麵的質(zhì)量就越差。發生拋光過度有二種現象:即是"橘皮"和"點蝕"。拋光過度多發生於機械拋光。

1、 Excessive polishing: the problem encountered in the daily polishing process is "excessive polishing", which means that the longer the polishing time, the worse the quality of the mold surface. There are two phenomena of excessive polishing: orange peel and pitting. Excessive polishing often occurs in mechanical polishing.

二、消除工件(jiàn)"橘(jú)皮"的措施:當發現表麵質量拋得不好時,許多人就(jiù)會增加拋(pāo)光的(de)壓力和延長拋光的時間,這種作法往往會使表(biǎo)麵的質量變得差。可采用以(yǐ)下的方法(fǎ)去補救(jiù):

2、 Measures to eliminate the "orange peel" of workpieces: when it is found that the surface quality is not polished well, many people will increase the polishing pressure and prolong the polishing time, which often makes the surface quality worse. The following methods can be used to remedy:

(1)把有(yǒu)缺陷的表(biǎo)麵去除,研磨(mó)的粒度比先前使用砂(shā)號略粗一級,然後進行研磨,拋光的力(lì)度要(yào)比先前的低一些。

(1) Remove the defective surface, grind the particle size slightly thicker than the previous sand number, and then grind it. The polishing force is lower than the previous one.

(2)以低於回火溫(wēn)度(dù)25℃的溫度進行應力消除,在拋光前使(shǐ)用細的砂號進行研(yán)磨,以(yǐ)較輕(qīng)的力度進行拋光。

(2) Stress relief shall be carried out at a temperature 25 ℃ lower than the tempering temperature. Before polishing, grind with a fine sand number and polish with a light force.

三、工件表麵"點蝕"形成的原因

3、 Causes of "pitting corrosion" on workpiece surface

由於在鋼(gāng)材中有些非金屬的(de)雜質,通常是硬而脆的氧化物,在拋光過程(chéng)中從鋼材(cái)表麵被拉出,形成微坑或點蝕,產生"點蝕"的主要因素有以下幾(jǐ)點:

Some non-metallic impurities in steel, usually hard and brittle oxides, are pulled out from the steel surface during polishing to form micro pits or pitting corrosion. The main factors causing "pitting corrosion" are as follows:

(1)拋光(guāng)的壓力過大,拋光時間過長。

(1) The polishing pressure is too high and the polishing time is too long.

(2)鋼(gāng)材的純淨度不夠,硬性(xìng)雜質(zhì)的含量高。

(2) The purity of steel is not enough and the content of hard impurities is high.

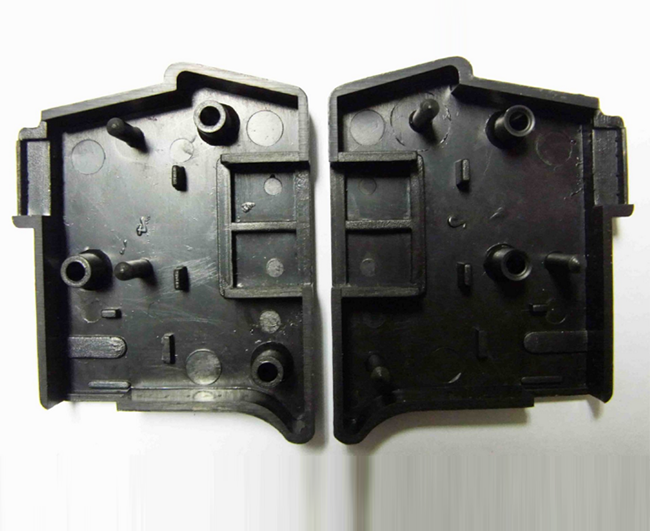

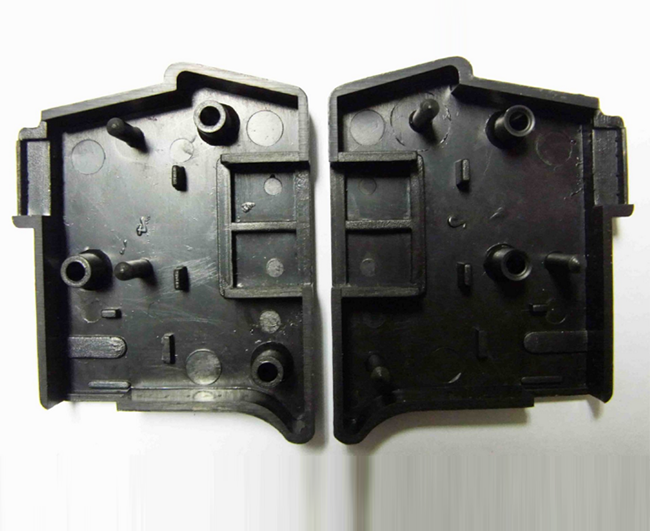

(3)模具(jù)表麵生鏽。

(3) The mold surface is rusty.

(4)黑皮料未清(qīng)除(chú)。

(4) The black leather is not removed.

(5)小心地將表(biǎo)麵重新研磨,砂粒粒度比先前(qián)所使用的粒度(dù)略粗(cū)一級,采用軟質及削銳的油石進行後步驟的研磨才再進行拋光程(chéng)序。

(5) Carefully regrind the surface. The sand particle size is slightly thicker than that previously used. Use soft and sharp oilstone for subsequent grinding before polishing.

(6)當砂粒尺寸小於1mm應避免采(cǎi)用軟的拋光工具。

(6) When the sand size is less than 1mm, soft polishing tools shall be avoided.

(7)盡可能采用短的拋光時間和小的拋光力度(dù)。

(7) Use as short polishing time and small polishing force as possible.

工件(jiàn)出(chū)現"橘皮"的原因:不規則粗糙的表麵被(bèi)稱為"橘皮",產生"橘皮"有許多的原因,常見的原因是由於模具表麵過熱或滲碳過度而引起,拋光(guāng)壓力過大及拋光時間過長是產生"橘皮"的主要原因。比如:拋光輪拋光,拋光輪產(chǎn)生的熱量會很容易造成"橘皮"。較硬的鋼(gāng)材能承受的拋光(guāng)壓力會大一些,相對較軟的(de)鋼材容易發生拋光過度,研究證明產生拋光過度的時(shí)間會因鋼材的硬度(dù)不同而有所不同(tóng)。

Reasons for "orange peel" of workpiece: irregular and rough surface is called "orange peel". There are many reasons for "orange peel". The common reasons are caused by overheating or excessive carburization of mold surface. Excessive polishing pressure and too long polishing time are the main reasons for "orange peel". For example: polishing wheel polishing, the heat generated by the polishing wheel will easily cause "orange peel". The harder steel can bear more polishing pressure, and the softer steel is prone to over polishing. The research shows that the time of over polishing varies with the hardness of the steel.