現在有很多模具製造商,要想在這樣的廠家中脫穎而出,注塑工(gōng)藝(yì)一定要好,否則很難有回頭客,影(yǐng)響廠家的盈(yíng)利能力。那麽(me)如何(hé)進行注塑成型呢?下麵就一起來(lái)了解一下吧。

Now there are many mold manufacturers. If they want to stand out among such manufacturers, the injection molding process must be good. Otherwise, it is difficult to have repeat customers, which will affect the profitability of the manufacturers. So how to carry out injection molding? Let's take a look.

注塑成型是一個(gè)知識麵廣、技術性強、實用性強的行業。注塑生產過程中需要塑料(liào)原料、色粉、水口材料、模具、注塑機、周邊設備、治具、噴劑、各種配件和包裝材料,給注塑車間的管理帶來大量工(gōng)作.與其他行業或(huò)部門相比,對注塑車間各級管理(lǐ)人員的要(yào)求更高。

Injection molding is an industry with a wide range of knowledge, strong technology and strong practicality. Plastic raw materials, toner, nozzle materials, molds, injection molding machines, peripheral equipment, fixtures, sprays, various accessories and packaging materials are required in the injection molding production process, which brings a lot of work to the management of the injection molding workshop Compared with other industries or departments, the requirements for managers at all levels in the injection molding workshop are higher.

注塑(sù)生產需要24小(xiǎo)時連續(xù)運轉。一(yī)般為(wéi)雙麵、三刀班或三班製。注塑車間工作崗位(wèi)多,分工複雜。不同職位的技能要求也不同。為了使注(zhù)塑車間的生產經(jīng)營順利進行(háng),需要對每個環節、每個(gè)崗位(wèi)所涉及的人員、材料、設備、工具等進(jìn)行管理,主要包括:原料室、邊角料室、配料間(jiān)、生產現場、後處理區、工具間(jiān)、半成品區、辦公室等(děng)區(qū)域的運行與協調管理。

Injection molding production requires 24-hour continuous operation. Generally, it is double-sided, three knife shift or three shift system. Injection molding workshop has many jobs and complicated division of labor. Different positions have different skill requirements. In order to ensure the smooth production and operation of the injection workshop, it is necessary to manage the personnel, materials, equipment and tools involved in each link and each post, mainly including the operation and coordination management of the raw material room, scrap room, batching room, production site, post-processing area, tool room, semi-finished product area, office and other areas.

Injection type:

1、橡膠注射成型:橡膠(jiāo)注射成型是(shì)將橡膠材料從機筒內直接(jiē)注入模型中進行硫化的一種生產方法(fǎ)。橡(xiàng)膠注射成型的優點是:雖然(rán)是間歇操(cāo)作,但成型(xíng)周期短,生產效率高,取消(xiāo)了製坯工序,勞動強度小(xiǎo),產品質量優良。

1. Rubber injection molding: rubber injection molding is a production method that directly injects rubber materials from the barrel into the mold for vulcanization. The advantages of rubber injection molding are: although it is an intermittent operation, the molding cycle is short, the production efficiency is high, the blank making process is cancelled, the labor intensity is small, and the product quality is excellent.

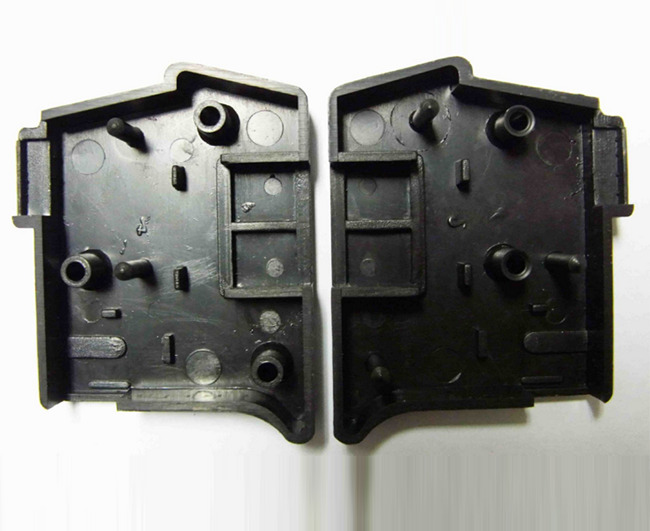

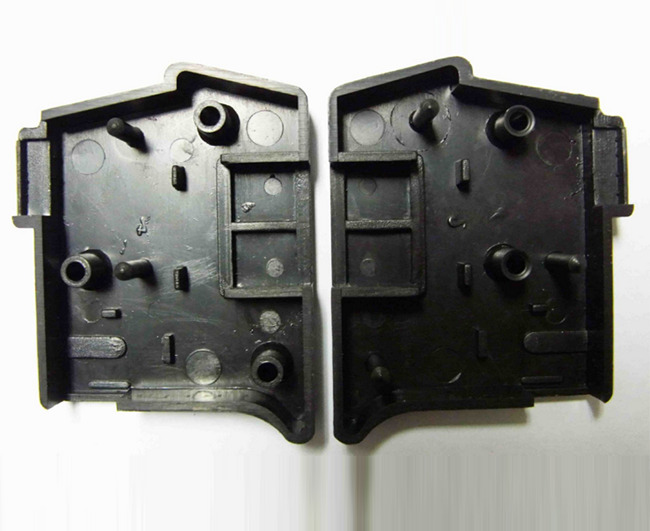

2、塑料注射成型:塑料注射成(chéng)型是塑料製品的一種方法。將熔融的塑料通過壓力注入(rù)塑料製(zhì)品的(de)模具中,經冷卻(què)成型得到所需的塑件。有專門用於進行注塑(sù)成型(xíng)的機械注塑機(jī)。今天常用的塑料(liào)是聚苯乙烯。由此(cǐ)產生的形狀通常是一種後產品,在安裝(zhuāng)或用作終產品(pǐn)之前不需要進(jìn)一步處理。許多細節,例如凸(tū)台、肋和螺紋,都可(kě)以在一(yī)次注塑成(chéng)型操作中形(xíng)成。

2. Plastic injection molding: plastic injection molding is a method of plastic products. The molten plastic is injected into the mold of the plastic products through pressure, and the required plastic parts are obtained by cooling and forming. There are mechanical injection molding machines specially used for injection molding. The plastic commonly used today is polystyrene. The resulting shape is usually a post product that requires no further treatment before installation or use as an end product. Many details, such as bosses, ribs, and threads, can be formed in one injection molding operation.

以上就是問題解答的相關內容了,希(xī)望能夠幫(bāng)助到大(dà)家,如對(duì)這一問題還存在(zài)任何疑問,都(dōu)歡迎關注(zhù)我們網站

http://www.lsjtcyjt.cn並谘詢我們的工作人員,將竭誠為您服務。

The above is the relevant content of the question answer. I hope it can help you. If you still have any questions about this problem, you are welcome to follow our website http://www.lsjtcyjt.cn And consult our staff, will serve you wholeheartedly.